ORELTECH

SOLUTIONS FOR FUNCTIONAL METAL COATINGS

GOLD AND PLATINUM LAYERS FOR SENSOR AND MEDTECH APPLICATIONS

OrelTech technology enables the manufacturing of high- purity biocompatible gold and platinum layers. Take your production to the future with OrelTech’s low-energy technology that lead to lowering your carbon footprint and production cost.

OrelTech metallization liquids are free from solid content, which creates gold and platinum layers that are free from organic residues. Choose between OTech Conductive Inks for high-precision pattern printing or OTech Coating Solutions for full area 2D/3D coating.

OTech metallization liquids are perfect for application in sensing (e.g. electrochemical sensors, biosensors), microfluidic systems, and various healthcare wearables for near-body applications.

MADE IN GERMANY

Leave behind outdated manufacturing processes.

Choose OrelTech Metallization Solutions and benefit from:

Manufacture thin Au and Pt layers of medical-grade purity, tested for biocompatibility under the conditions required by ISO 10993 standard.

Low-temperature curing process enables deposition on delicate substrates such as polymers, paper, or fabric.

Economic and environmental benefits from minimized use of precious metals, energy consumption and low chemical waste.

High-precision controlled deposition of precious metals with particle-free OTech Metallization Liquids using inkjet printing and other technologies.

USE CASE #1: Biocompatible (bio)sensors

OTech Aurum and OTech Platinum inks allow precision printing (~50 µm line width) of high-purity gold and platinum electrodes on thin and flexible substrates such as polymers, paper or fabric.

OrelTech inks have a unique nanoparticle- and polymer-free formulation, which enables formation of pure metal layer without organic contaminants. The purity of the layers have been confirmed for biocompatibility by testing under the same conditions required by ISO 10993 standard.

The electrodes and sensors are ideal for applications in healthcare wearables, biosensors, neuroelectrodes or microfluidics.

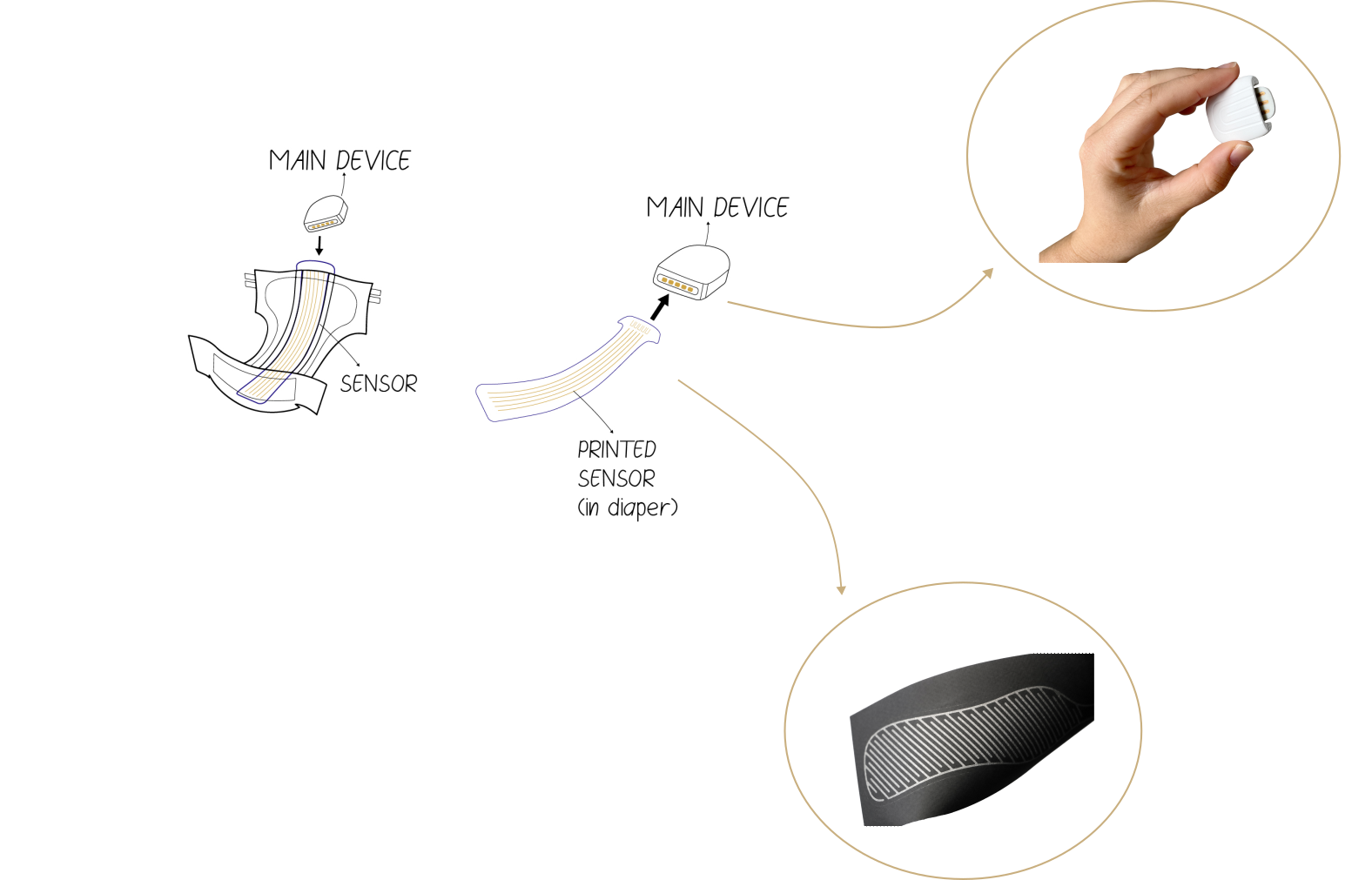

USE CASE #2: Printed gold contact and disposable silver moisture senzor for small healthcare device

In partnership with Pilotfish Berlin GmbH, we developed a prototype of a smart incontinence management device, which lightness increases a wearer’s comfort. OTech Aurum ink has been used to create a repeat-use gold contact that consists of 3 conductive lines less than 1 µm in thickness.

Additionally, the sensor itself is designed as a one-time-use paper device which can be inserted in diapers and is also printed with OTech Jet silver ink (0,5 µm thickness). Once the sensor detects moisture, the device alerts the user to change it.

The prototype demonstrates how the use of economical base materials coupled with rational and highly-controlled use of precious metals, opens up new ways to affordable bioelectronic point-of-care diagnostic devices.

USE CASE #3: Gold-coated ECG buttons

In the manufacturing of disposable ECG electrodes, process and material costs are the major cost components. Established processes such as PVD or plating requiring either high-vacuum or large volumes of toxic chemicals can be replaced with the simple two-step process of OrelTech technology: deposit and cure. It saves energy and precious metal.

We temaed up with electroplating experts at Biocenex GmbH for a joint project of coating plastic ECG buttons. Compared to currently established electrochemical process, OrelTech coating technology leads to thinner, highly conductive layers. In the process, only one chemical is used and no wastewater is produced. The total area needed for manufacturing setup with OrelTech technology takes less than 20% of an equivalent electroplating plant.

The resulting layers are of high purity and thus biocompatible and safe for use in contact with the skin.

Check more of our products here

Talk to us

To achieve flawless integration, we collaborate closely with our customers from first feasibility tests to fine-tuning mass production. In this way, our customers benefit from customized solution with added value and efficiency from process to product while lowering your environmental impact.

Curious to learn more? Drop us a message in the contact form below and schedule a 1-on-1 meeting to talk to our experts.

OrelTech GmbH

Rudower Chaussee 29

12489 Berlin

Germany